language

English

العربية

বাংলাদেশ

Български

Hrvatski

Česky

Dansk

Nederland

Esperanto

Esperanto

Slovenski

Filipino

Suomi

Français

Maori

Shqiptare

Shqiptare

Georgian

Euskara

Euskara

Deutsch

Ελλάδα

ישראל

इंडिया

Magyarország

Ísland

Indonesia

Irlanda

Italia

日本語

Sovensko

Հայաստան

한국

Kyrgyz

ປະເທດລາວ

Zulu

Zulu

Latvian

Lithuanian

Luxembourgish

Latinus

Latinus

Macedonian

Малайская

Maltese

Монгол улс

Cymraeg

Cymraeg

ဗမာ

தமிழ்

தமிழ்

नेपाल

Norge

ایران

Polska

Portugal

România

Российская

Србија

Slovak

Slovak

Србија

Slovak

Slovak

Bosanski

Slovenian

Беларус

España

Sverige

Точик

ประเทศไทย

Türk

Azərbaycan

Uzbek

Afrikaans

Afrikaans

Việt Nam

language

20

2025

-

09

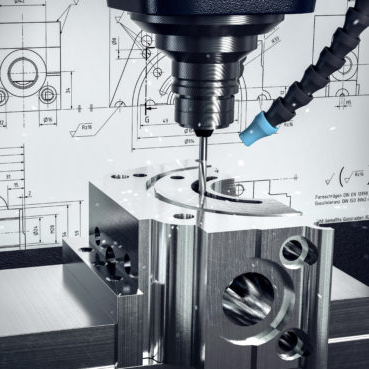

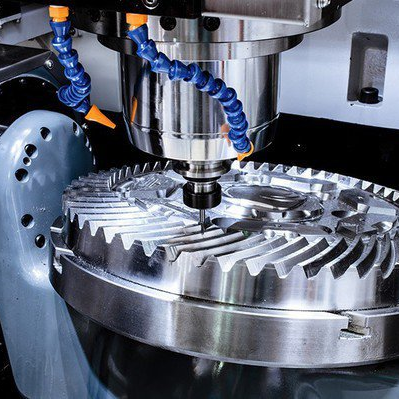

3-Axis vs 5-Axis CNC? Choose Right to Save 50% Cost

3-axis fits high-volume low-complexity parts ($15k-$75k purchase, 10%-15% rework); 5-axis suits low-volume high-complexity parts ($120k-$450k purchase, ≤2% rework). 3-step selection (check part features→calculate batch break-even→plan future) cuts 50% costs, avoiding idleness/rework.

- 3-axis: Only X/Y/Z linear motion; 3-5 clampings for polyhedrons, cumulative error 0.05-0.1mm, fit for 2.5D tasks (planar milling), Ra1.6μm.

- 5-axis: Adds A/C axes (±120°/360° rotation); one clamping for 5-sided machining, RTCP ensures ±0.003mm precision, Ra0.4μm, fit for complex surfaces (turbine blades)

2. Cost Structure

- 3-axis: High-volume low-complexity (auto brackets, batch ≥1k units);

- 5-axis: Low-volume high-complexity (medical implants, ±0.005mm tolerance).

Selection Pitfalls

- Blindly choosing 5-axis: 15%-20% lower efficiency, 30% higher energy for simple parts;

- Making do with 3-axis: Precision loss from multiple clampings, $120k extra rework in 6 months;

- Curved surfaces = 5-axis: Simple curves (phone case) use "3-axis + $750 fixture", save $180k.

3-Step Selection

- Check parts: Spatial angles/need 3+ surfaces in 1 clamping? 2 "no"s → 3-axis;

- Calculate batches: Critical volume = (5-axis-3-axis price gap) ÷ unit cost gap;

- Plan future: For complex parts in 1-2 years, choose 3-axis with 4th axis interface, or small 5-axis ($120k-$150k).

Industry Applications

- Auto: Brackets with 3-axis ($75k-$120k/line, 60% cheaper), motor rotors with 5-axis (40% faster);

- Medical: Implants need 5-axis (precision + anti-contamination), infusion parts with 3-axis (70% cost cut);

- Molds: Consumer goods with "3-axis + 4th axis", auto panels with 5-axis (50% more efficient).

Key words:

#3Axis vs 5Axis CNC #CNCMachineSelection #CNCCostSaving #5AxisMachiningBenefits #3AxisCNCApplications #CNCLifecycleCost #PrecisionMachiningTips #CNCInvestmentGuide

Related news

undefined