language

English

العربية

বাংলাদেশ

Български

Hrvatski

Česky

Dansk

Nederland

Esperanto

Esperanto

Slovenski

Filipino

Suomi

Français

Maori

Shqiptare

Shqiptare

Georgian

Euskara

Euskara

Deutsch

Ελλάδα

ישראל

इंडिया

Magyarország

Ísland

Indonesia

Irlanda

Italia

日本語

Sovensko

Հայաստան

한국

Kyrgyz

ປະເທດລາວ

Zulu

Zulu

Latvian

Lithuanian

Luxembourgish

Latinus

Latinus

Macedonian

Малайская

Maltese

Монгол улс

Cymraeg

Cymraeg

ဗမာ

தமிழ்

தமிழ்

नेपाल

Norge

ایران

Polska

Portugal

România

Российская

Србија

Slovak

Slovak

Србија

Slovak

Slovak

Bosanski

Slovenian

Беларус

España

Sverige

Точик

ประเทศไทย

Türk

Azərbaycan

Uzbek

Afrikaans

Afrikaans

Việt Nam

language

01

2025

-

10

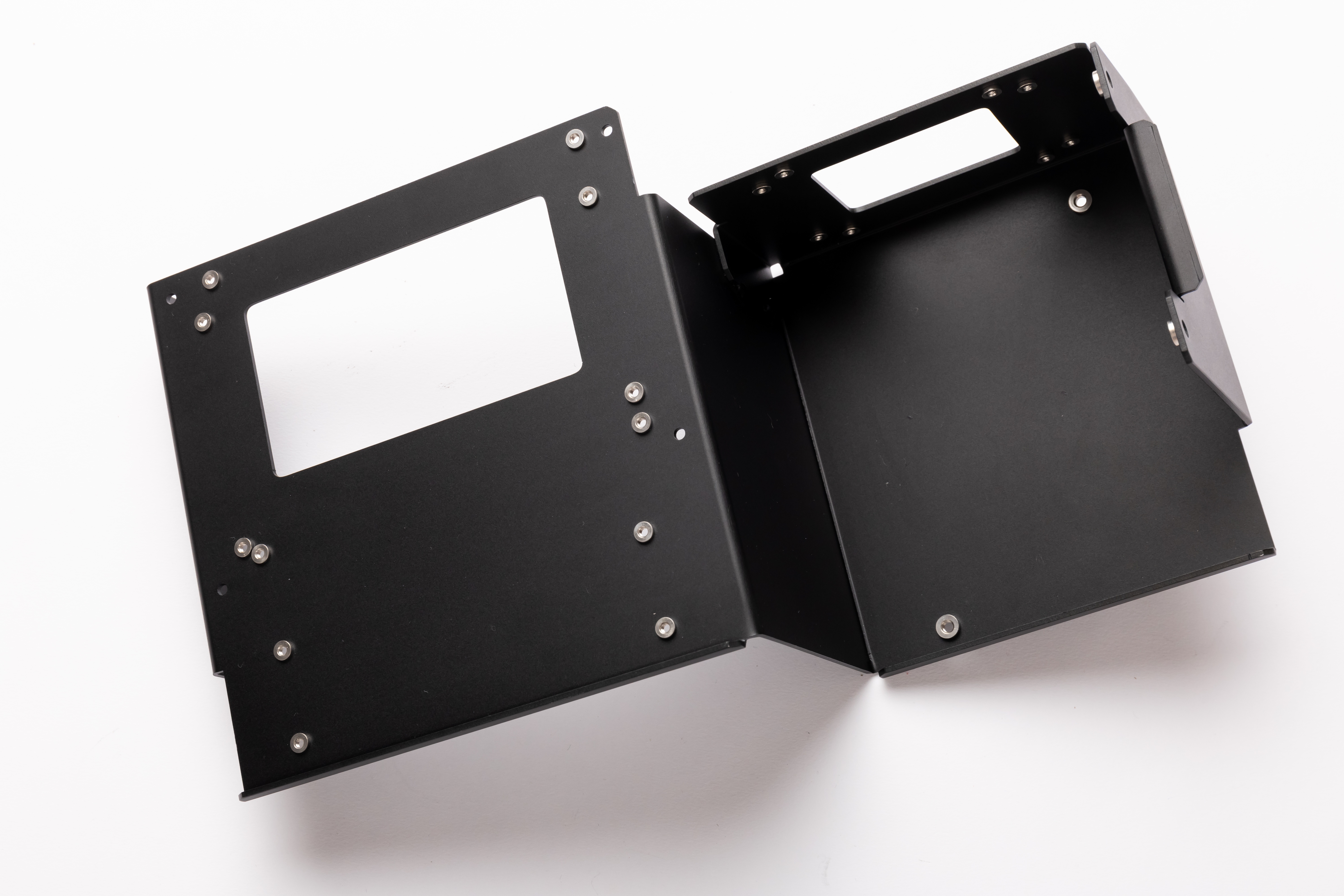

Sheet Metal Design Keeps Going Wrong? 7 Rules Novices Must Read

Common mistakes of sheet metal design novices can be avoided with 7 core rules: follow the "4T Rule" to prevent bending deformation, mark datum and thickness in 3D models for process adaptation, unify bend radius to reduce mold costs, fully label hardware specifications to avoid installation misalignment, choose surface treatment by scenario to control costs, balance performance and manufacturability for material selection, and ensure U-channel width-to-height ratio ≥2:1 for strength. Mastering these rules reduces 90% of design errors, aligning with the industry's demand for lightweight and cost-efficiency.

Key words:

#SheetMetalDesignRules #4TRuleSheetMetal #SheetMetalBendRadius #SheetMetalMaterialSelection #SheetMetalSurfaceTreatment #NoviceSheetMetalGuide #SheetMetalStructuralDesign #SheetMetalManufacturability

Related news

undefined