Esperanto

Esperanto

Shqiptare

Shqiptare

Euskara

Euskara

Zulu

Zulu

Latinus

Latinus

Cymraeg

Cymraeg

தமிழ்

தமிழ்

Slovak

Slovak

Slovak

Slovak

Afrikaans

Afrikaans

Welcome to Marigold Rapid Blog Page!

We share information and knowledge we have hard earned from our many years of experience in the rapid prototyping and custom manufacturing industry. We hope these articles can help you to optimize your product design and better understand the world of rapid prototyping CNC machining, injection molding, sheet metal fabrication and die casting manufacturing.

05

2025

-

05

Why Have CNC Instrument Enclosures Parts Become the Core Choice for High-End Equipment Protection

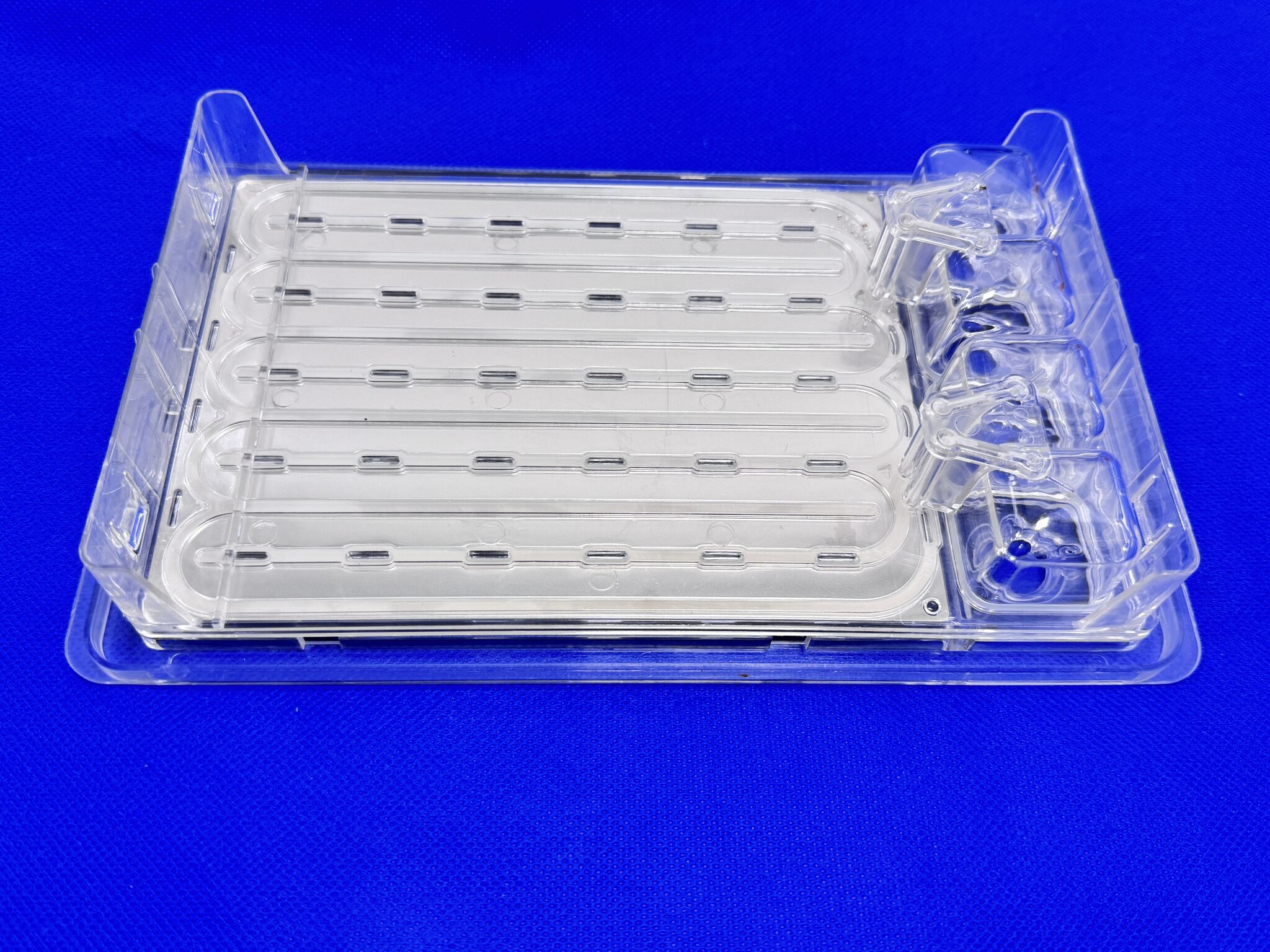

As precision instruments continue to move towards miniaturization and intelligence, higher requirements are placed on the structural strength, processing accuracy, and heat dissipation performance of shell parts. CNC instrument enclosures parts stand out in this context. It achieves high consistency and high surface quality through CNC machining, providing a solid and reliable protective barrier for various types of high-precision equipment.

This type of part is usually made of high-strength materials and cut and formed by multi-axis CNC technology. It not only has a compact appearance and structure, but also has extremely fine details. The edges and corners have smooth transitions and precise holes, which effectively meet the installation requirements of internal core components. At the same time, its customization flexibility is extremely strong, adapting to different structural designs to meet the strict standards of personalized equipment.

CNC instrument enclosures parts are not just a "shell", but also a guardian of performance and safety. It carries multiple functions such as structural support, protective shielding, and heat dissipation management. It is an indispensable part of the stable operation of precision instruments, and also represents the dual upgrade of the manufacturing process level and the industrial design concept.

Key words:

Related news